Our Product Line: HONC Gas Generators

At HONC Gas, we offer a diverse range of gas generators tailored to specific applications — from domestic cooking to large-scale industrial operations. All our models generate HONC Gas on-demand, ensuring safety, energy efficiency, and ultra-low running costs.

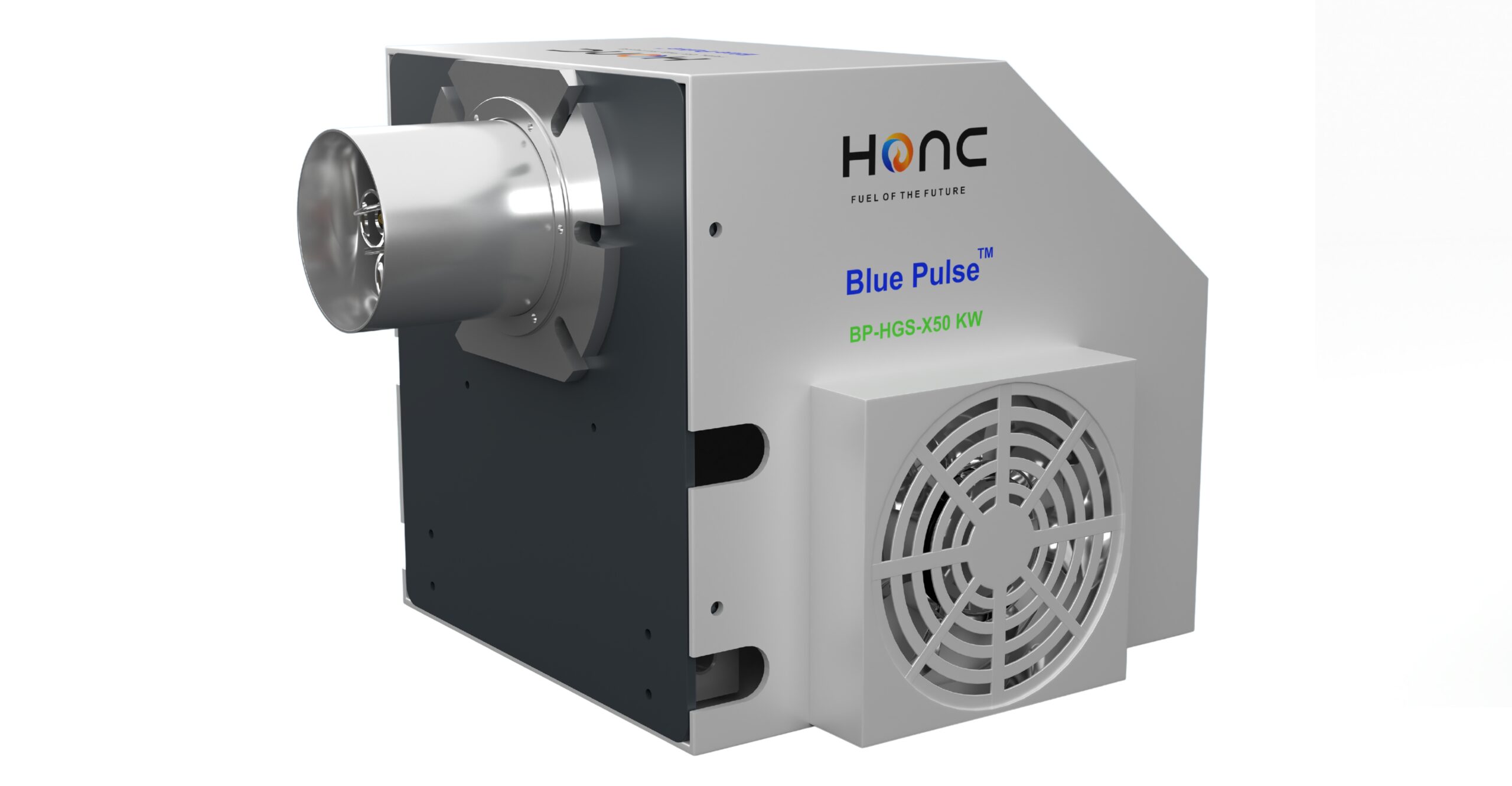

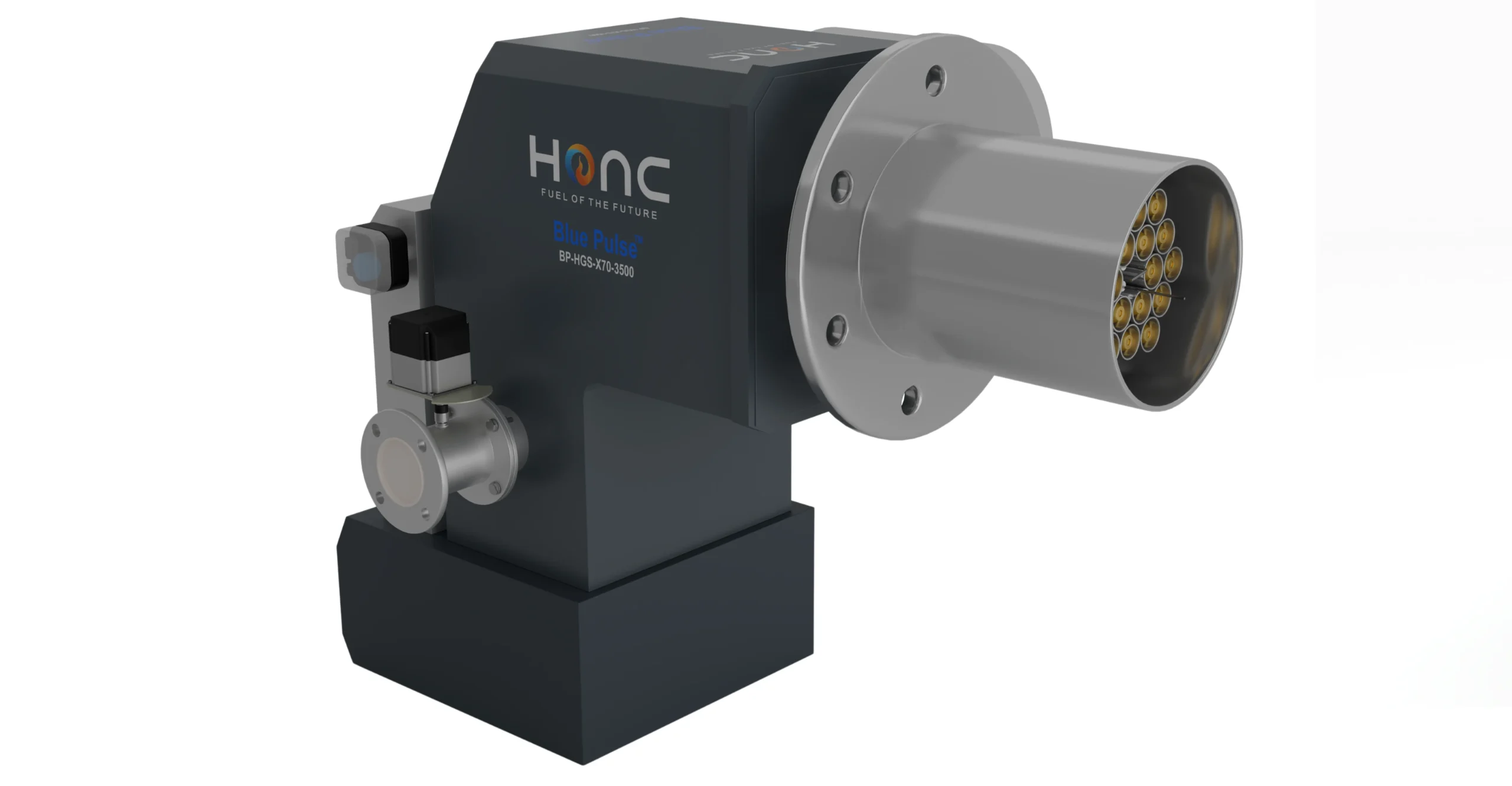

BluePulse™ Burner

The BluePulse™ Burner is the world’s first industrial burner designed to run exclusively on

HONC Gas — a patent applied green hydrogen fuel derived 100% from purified water.

| Feature | Specification |

|---|---|

| Thermal Output Range | 70 kW to 3500 kW |

| Fuel Type | 100% HONC Gas (No LPG or other fuels required) |

| Combustion Efficiency | >98% |

| Ignition System | Auto pulse ignition with safety lockout |

| Control Type | Modulating / Two-stage / On-Off (customizable) |

| Flame Detection | Ionization or UV sensor-based |

| Mounting Options | Horizontal / Vertical |

| Material | Stainless steel, high-temperature ceramic liner |

| Noise Level | <75 dB |

Domestic Cooking Series

Ideal for households, community kitchens, temples, or remote areas where LPG is costly or unavailable.

| Model Name | Output Capacity | No. of Burners Supported | Key Features |

|---|---|---|---|

| HGS-DC1 | 1,000 LPH | Single Burner | Compact design, lightweight, safe for home use |

| HGS-DC2 | 2,000 LPH | Two Burners | Stable flame, auto-ignition, low power draw |

| HGS-DC4 | 4,000 LPH | Four Burners | Suitable for community cooking, temples, large households |

Commercial Cooking Series

Ideal for Small or large restaurants, hostels, temples, industrial kitchen, hospitals, canteens

| Model Name | Output Capacity | No. of Burners Supported | Application |

|---|---|---|---|

| HGS-CC4 | 4,000 LPH | Up to 4 Burners | Small restaurants, hostels |

| HGS-CC8 | 8,000 LPH | Up to 8 Burners | Large restaurants, temples |

| HGS-CC12 | 12,000 LPH | Up to 12 Burners | Industrial kitchens, hospitals, canteens |

Industrial Boiler Series

Designed for small scale factories, sampling units, mid-sized garments or dyeing units, medium scale continuous operations and large scale industrial application

| Model Name | Output Capacity | Compatible Boiler Size | Application |

|---|---|---|---|

| HGS-IB5 | 5,000 LPH | 50–100 kg boilers | Small-scale factories, sampling units |

| HGS-IB10 | 10,000 LPH | 100–200 kg boilers | Mid-sized garment or dyeing units |

| HGS-IB30 | 30,000 LPH | 300–500 kg boilers | Medium-scale continuous operations |

| HGS-IB50 | 50,000 LPH | 500–1000 kg boilers | Large-scale industrial applications |

Furnace & Melting Series

Designed for batch and continuous metal melting operations, including iron, aluminum, brass, and high-temperature heat treatment lines.

| Model Name | Output Capacity | Max Temp Support | Application Type |

|---|---|---|---|

| HGS-FM25 | 25,000 LPH | Up to 1,800°C | Batch melting (aluminum, brass) |

| HGS-FM50 | 50,000 LPH | Up to 2,800°C | Continuous melting or heat treatment lines |

Cutting, Welding & Heating Series

Designed for light to heavy-duty cutting, welding, and forging operations across fabrication shops and structural applications.

| Model Name | Output Capacity | Max Temp Support | Application |

|---|---|---|---|

| HGS-CWH10 | 10,000 LPH | Up to 2,700°C | Light welding, local cutting |

| HGS-CWH25 | 25,000 LPH | Up to 2,750°C | Fabrication shops, structural steel |

| HGS-CWH50 | 50,000 LPH | Up to 2,800°C | Heavy-duty laser cutting, forging |

Soldering & Brazing Series

Designed for precision soldering and brazing applications in electronics, HVAC, scientific labs, and jewelry making.

| Model Name | Output Capacity | Max Temp Support | Application |

|---|---|---|---|

| HGS-SB1 | 1,000 LPH | Up to 1,400°C | Motor coil, electrical component soldering |

| HGS-SB1.5 | 1,500 LPH | Up to 1,500°C | HVAC & heat exchanger coil brazing |

| HGS-SB3 | 3,000 LPH | Up to 1,600°C | Scientific glass labs, sealed tubes |

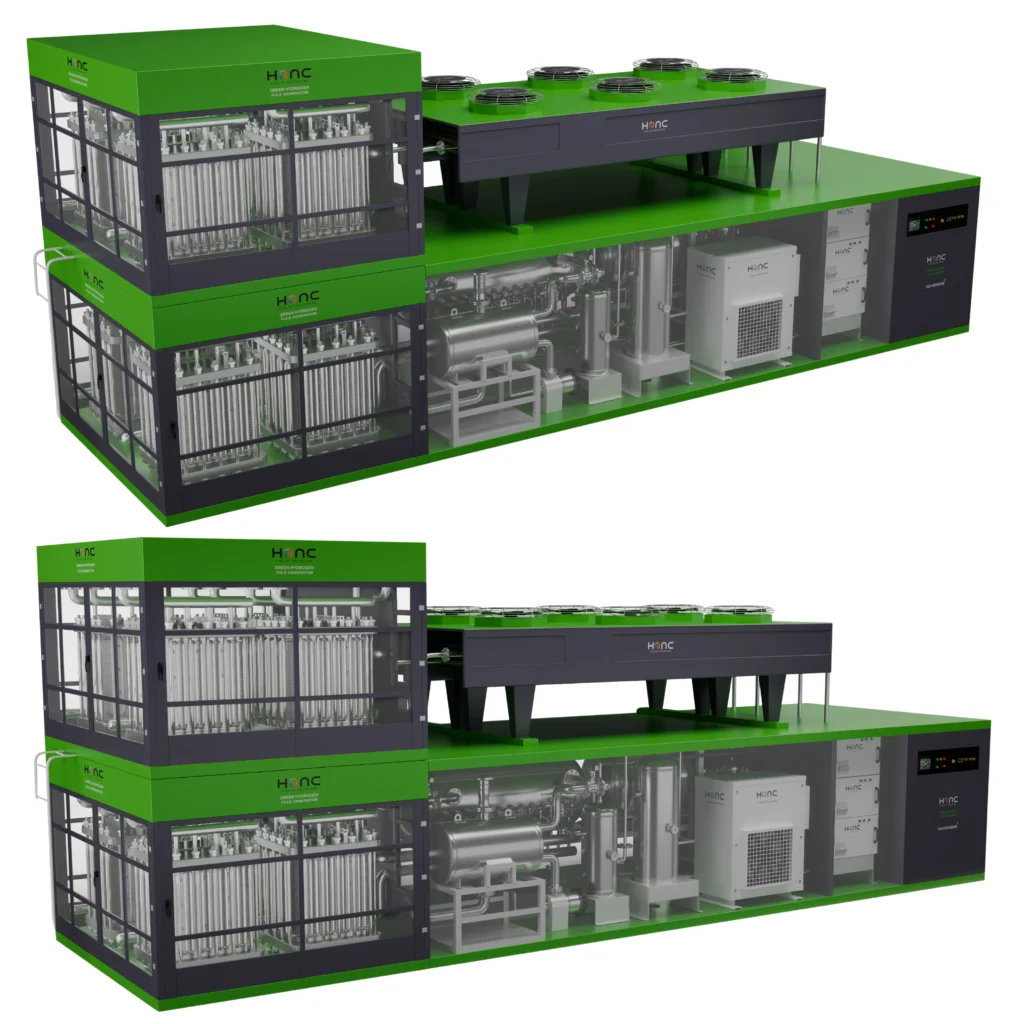

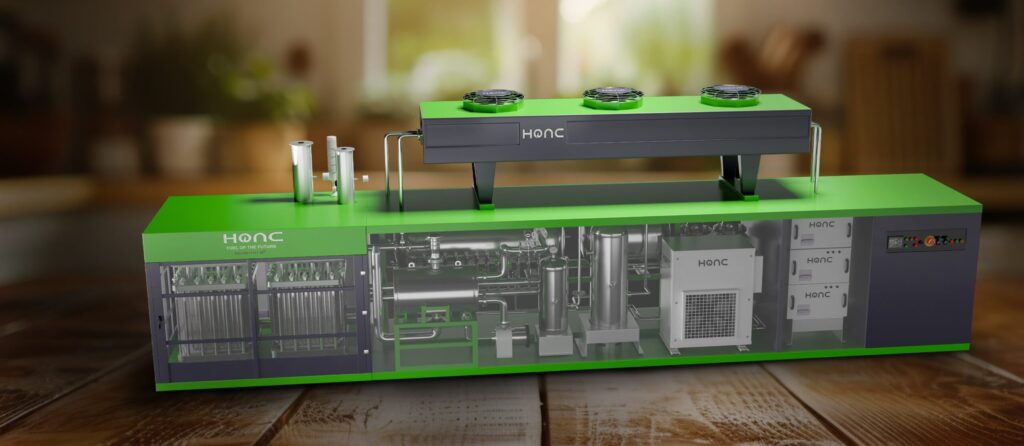

Industrial Plant Series

Engineered for high-capacity thermal systems in power plants, heavy industries, and large-scale utility operations.

| Model Name | Output Capacity | Boiler Size | Application |

|---|---|---|---|

| HGS-IP125+ | 125,000+ LPH (Custom) | 1000+ kg | Power plants, paper mills, central utilities |

| HGS-IP175+ | 175,000+ LPH (Custom) | 1500+ kg | Energy-heavy industries |

| HGS-IP225+ | 225,000+ LPH (Custom) | 2000+ kg | Mega thermal conversion |

| HGS-IP300+ | 300,000+ LPH (Custom) | 3000+ kg | Multi-factory clusters, export plants |

Other Applications of HONC Gas

Tailored for diverse industries—from bakeries to biotech—ensuring clean, efficient, and precise thermal performance across ovens, labs, production lines, and cold climates.

| Sector | Use Case Example | Benefit |

|---|---|---|

| Bakery & Food | Ovens, driers, roasters | No carbon, stable heat |

| Textile Processing | Drying, singeing, steam tunnels | Odorless flame, low emissions |

| Printing & Packaging | Film shrink, paper dryers | Spotless print quality, zero soot |

| Pharma & Chemical | Reactor heating, drying chambers | Flame purity, no residue |

| Candle/Wax | Continuous melting | No soot, shiny finish |

| Scientific Labs | Glass sealing, test heating | Controllable micro flames |

| Auto Workshops | Parts heating, flame-based cleaning | Safer than traditional torches |

| Plastic Forming | Pet bottle mold heating | Precision thermal control |

| Bio Waste | Low-emission incineration | Carbon-free decomposition |

| Cold Climate Heating | Room heating, pipe thawing, greenhouses | High performance in sub-zero conditions |

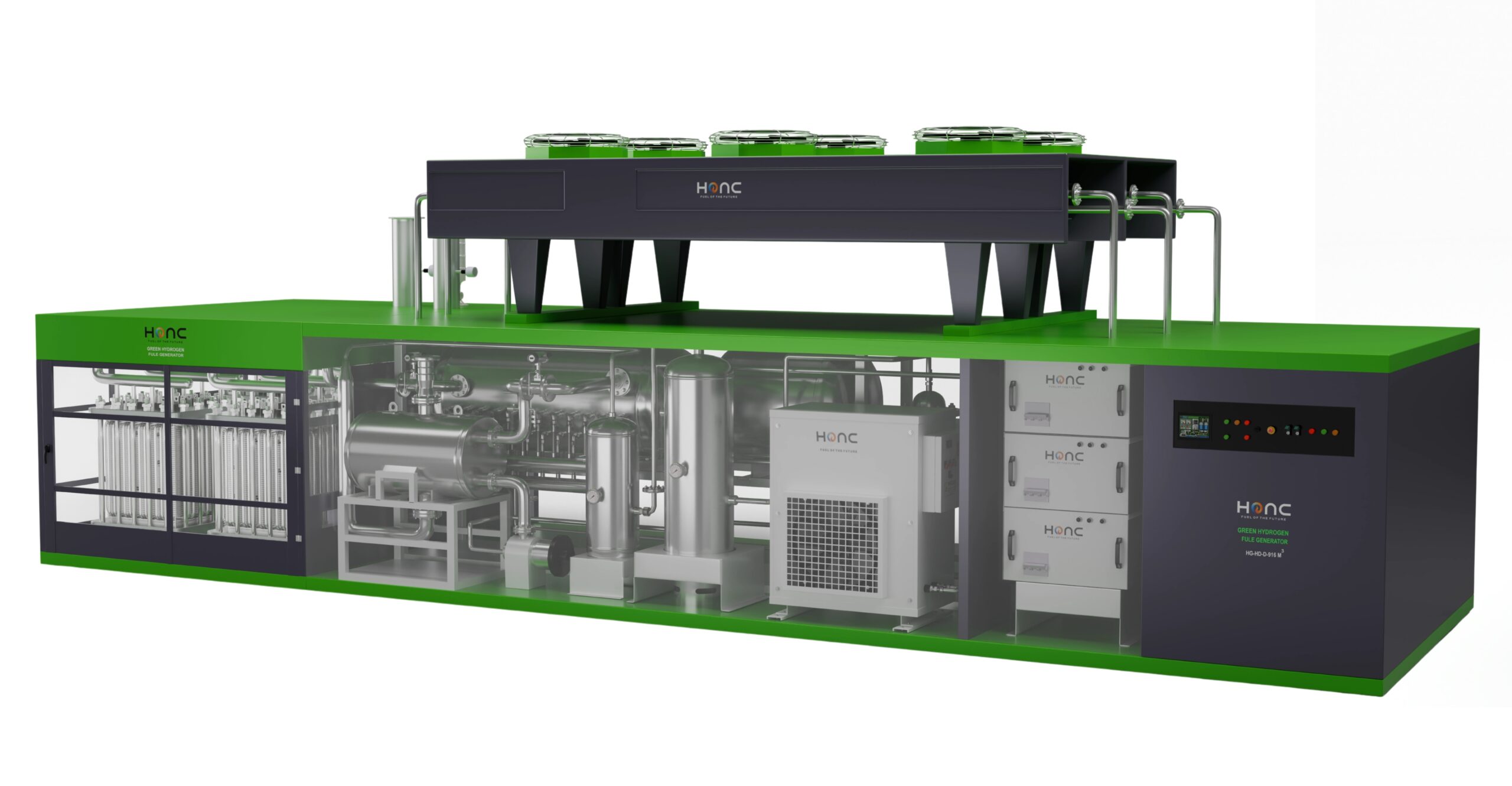

Our Product Line: HONC Gas Generators

At HONC Gas, we offer a diverse range of gas generators tailored to specific applications — from domestic cooking to large-scale industrial operations. All our models generate HONC Gas on-demand, ensuring safety, energy efficiency, and ultra-low running costs.

Industrial Boiler Series

Built to integrate with textile, garment, food processing, chemical industries, and now large-scale power plants using steam or thermal systems.

| Model Name | Output Capacity | Compatible Boiler Size | Application |

|---|---|---|---|

| HGS-IB5 | 5,000 LPH | 50–100 kg boilers | Small-scale factories, sampling units |

| HGS-IB10 | 10,000 LPH | 100–200 kg boilers | Mid-sized garment or dyeing units |

| HGS-IB30 | 30,000 LPH | 300–500 kg boilers | Medium-scale continuous operations |

| HGS-IB50 | 50,000 LPH | 500–1000 kg boilers | Large-scale industrial applications |

| HGS-IP100+ | 100,000+ LPH (Custom) | 1000 kg boilers and above | Power plants, paper mills, heavy industry |

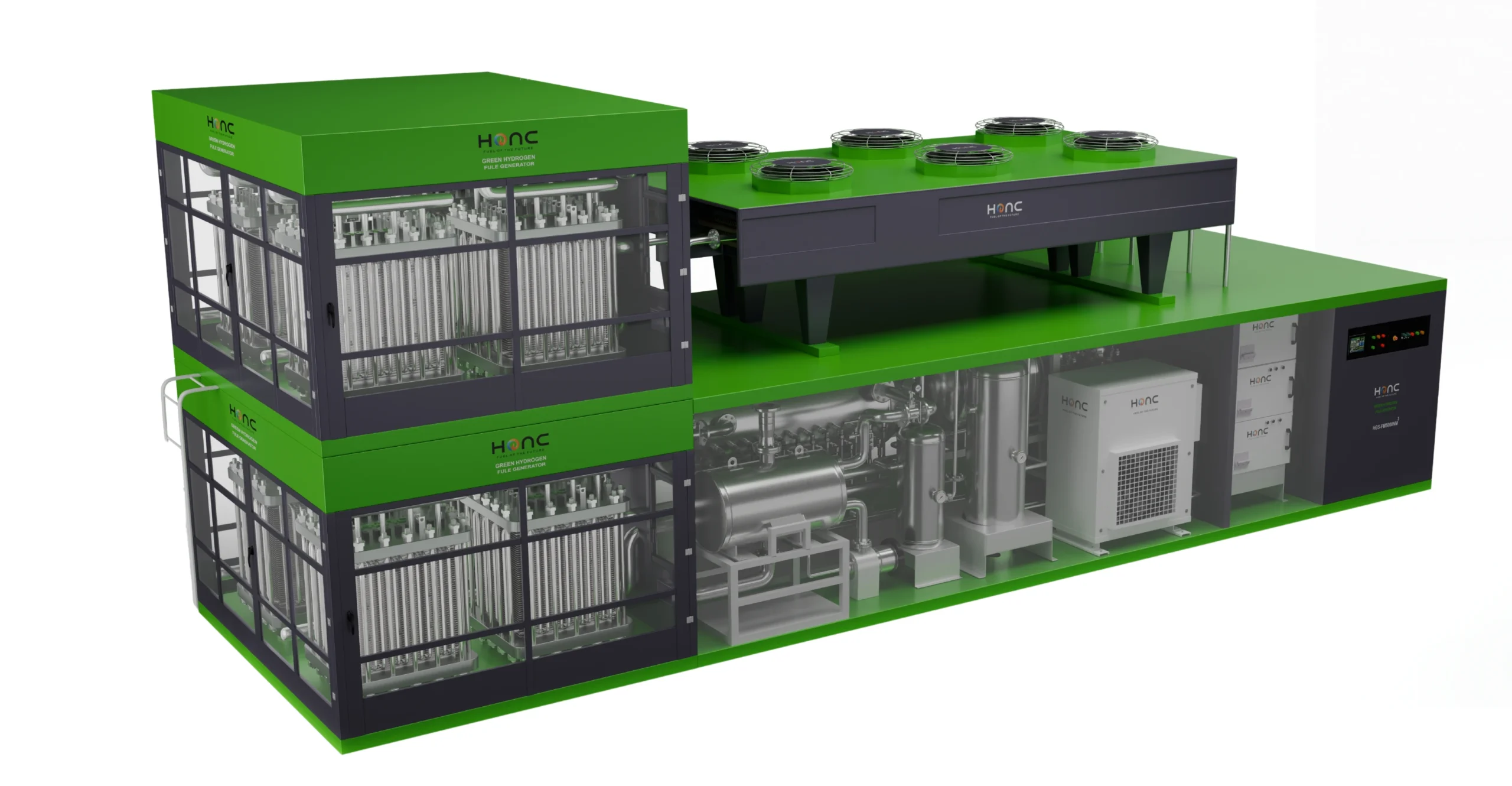

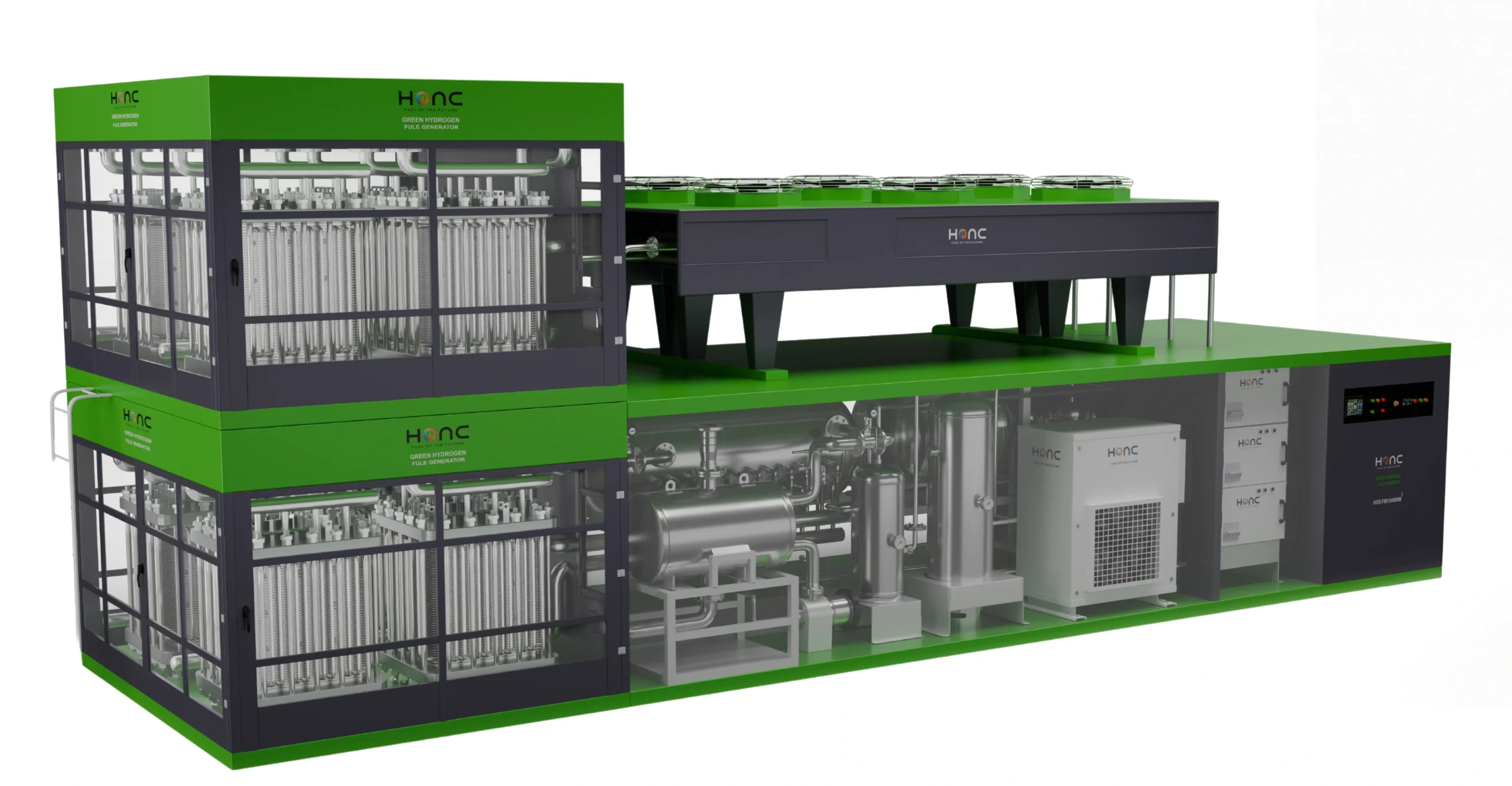

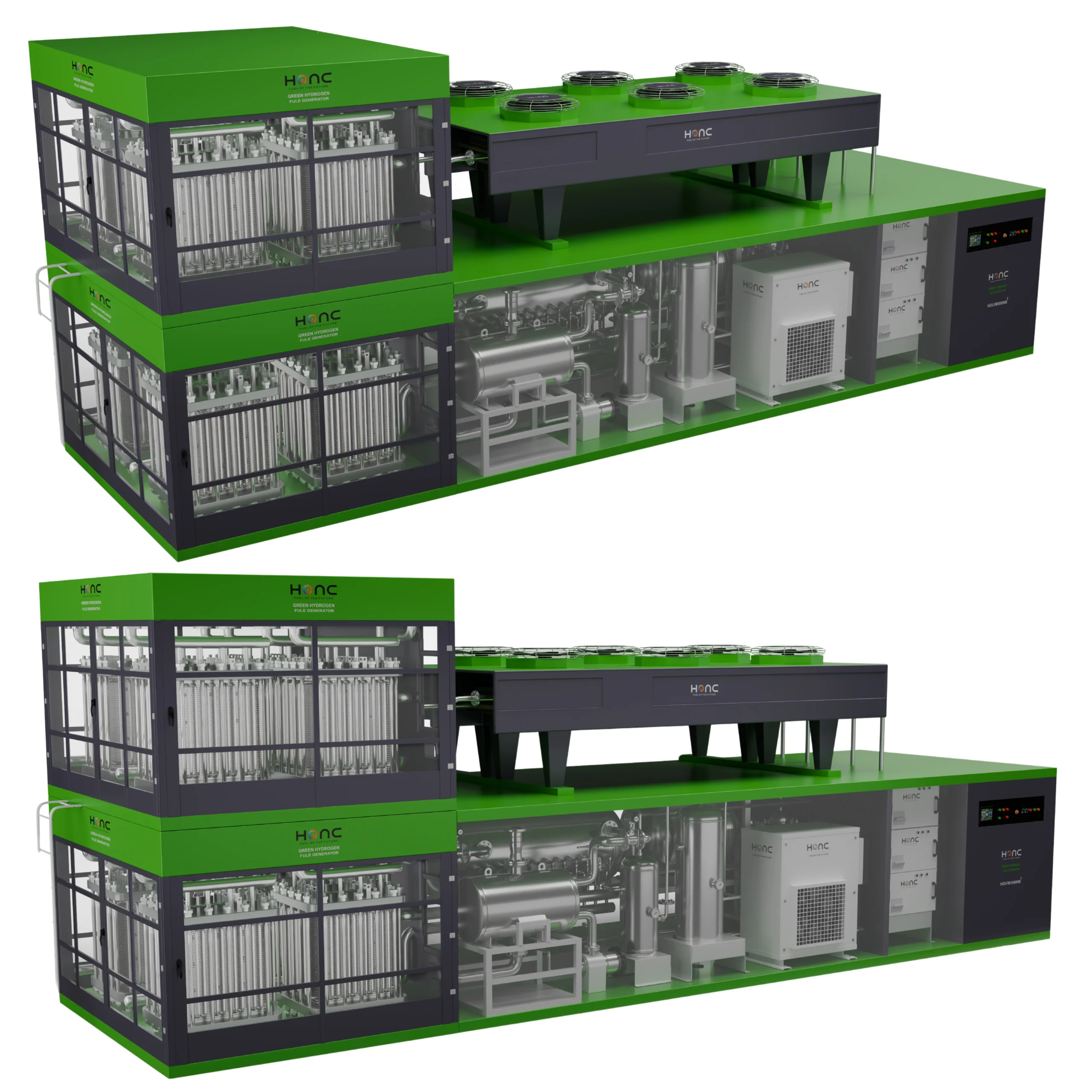

New Model For Industrial Plants

Model Name: HGS-IP100+

Output Capacity

Starting from 1,00,000 LPH (custom scalable)

Ideal For:

- Thermal & Power Plants

- Paper & Pulp Mills

- Centralized Multi-Boiler Plants

- Industrial Utility Service Providers

Key Features:

- Scalable design architecture

- High-pressure, multi-burner configuration

- Integrated with centralized control systems

- IoT-ready for 24/7 monitoring

- Custom-built for long-duration continuous operations